TRICKLE IMPREGNATION TECHNIQUE

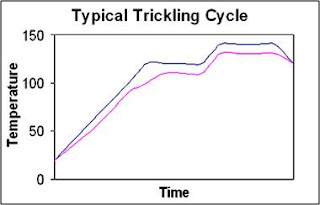

TRICKLE IMPREGNATION TECHNIQUE In today’s competitive world the electrical insulation materials and the processes are viewed with tremendous cost and quality consciousness. Varnishing of electrical machine winding forms a major part of the total cost of the electrical insulating materials. With the increasing costs of energy and solvents for use in varnishing, it has become a need of the hour to look into the change in the conventional impregnation methods such as Dip and bake varnishing or the Vacuum impregnation. On this background Trickle impregnation technique was evolved to improve the varnishing quality coupled with reduced cost. This technique is now well accepted and used for impregnating stators / fields and armatures / rotors in all the advanced countries. TRICKLE IMPREGNATION TECHNIQUE : The resin applied on the winding is quickly sucked through the slots. Assisted by the capillary action it pushes out the trapped air from the small voids and gaps in the winding