TRICKLE IMPREGNATION TECHNIQUE

TRICKLE IMPREGNATION TECHNIQUE

In today’s competitive world the electrical insulation materials and the processes are viewed with tremendous cost and quality consciousness. Varnishing of electrical machine winding forms a major part of the total cost of the electrical insulating materials. With the increasing costs of energy and solvents for use in varnishing, it has become a need of the hour to look into the change in the conventional impregnation methods such as Dip and bake varnishing or the Vacuum impregnation.

On this background Trickle impregnation technique was evolved to improve the varnishing quality coupled with reduced cost. This technique is now well accepted and used for impregnating stators / fields and armatures / rotors in all the advanced countries.

TRICKLE IMPREGNATION TECHNIQUE :

The resin applied on the winding is quickly sucked through the slots. Assisted by the capillary action it pushes out the trapped air from the small voids and gaps in the winding and penetrates evenly in all the voids.

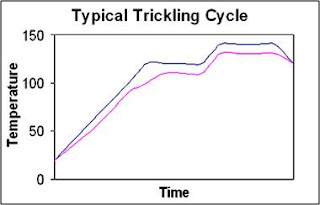

The essential point for successful application of the trickle impregnating resin is the correct adjustment and the control of the winding temperature.

The essential point for successful application of the trickle impregnating resin is the fine

setting and the control of the winding temperature.

DESIGN OF TRICKLE IMREGNATION PLANT

The design of a trickle Impregnation Plant plays a vital role in ensuring the uniform quality of a trickle impregnation. Any trickle impregnation plant should have the following essential features.

The trickle impregnation plants with the above features are custom built taking into account several factors such as production rate, size and shape of the component, type of trickle resin etc.

Mainly three types of trickle impregnation plants are popular for various types of components.

Multi Spindle Trickle Impregnation plant ( Batch type ) :

It is ideal for stators of A. C. motors. Depending on the production rate the quantity of the spindles can be decided.

MULTI SPINDLE ROTARY INDEXING TYPE TRICKLE PLANT :

It is ideal for medium size stators and rotors e.g. armature and field coils of hand tools, auto electrical, household

CONVEYORISED TRICKLE IMPREGNATION PLANT :

This plant is similar to that of indexing type. However a chain conveyor carries the components instead of indexing movement. This plant is especially suitable for large output of impregnated small and medium sized components.

Generally this plant is installed in a conveyor production line of components.

For More Details Visit, http://oildehydrationplant.com/trickle-impregnation-technique.html

hiii

ReplyDeletethank you for posting this blog.I read you blog and it it very useful for us.

I have one website related from your blog http://varnishingmachine.com/

Varnishing Machines suppliers in pune

Varnishing Machines exporters in pune

oil filter machines

oil filteration plants

oil filtration machines

oil purification

oil purification machines

oil purification plants

oil purifiers

industrial oil filtration machines

Oil filteration plants

Transformer oil filtration machines in pune

Transformer oil filtration plants manufacturer in pune

Transformation oil filtration machine in india

Mosquito Control Treatment in Balewadi

Integrated Mosquito Control Treatment in wagholi

Integrated,Mosquito Control Treatment Services in Pune

Integrated Mosquito Control Treatment Services in vishrantwadi

Integrated Mosquito Control Treatment Services in midc bhosari

Integrated Mosquito Control Treatment Services in hadapsar

Thank you.

Nice Blog,thanx for posting this wonderful blog.

ReplyDeleteAR Engineering is a company for manufacturing of transformer oil filtration machines. Since then AR Engineering has developed different types of Insulating Oil upgrading systems suitable for in-house and onsite operation.

Varnishing Machines exporters in pune

Trickle Impregnation Technique supplier in pune

Transformer Oil Filtration supplier in pune

Industrial Oil Purification Systems suppliers in pune

Batch Type Trickle Impregnating Machine

Index Type Trickle Impregnating Machine suppliers in pune

Batch Type Trickle Impregnating Machine manufacturer in pune

ReplyDeleteThis is excellent information. Thanks for sharing.

Top Manufacturer Of Transformer Oil Filtration And Dehydration Plants, Located In Satara Maharashtra. High-Vacuum Transformer Oil Filtration And Dehydration Plants are suitable for all types of electrical insulating oils

High-Vacuum Transformer Oil Filtration

Manufacturer Of Transformer Oil Filtration Plants

Supplier Of Transformer Oil Filtration Plants

Exporter Of Transformer Oil Filtration Plants

Transformer Oil Filtration Plants In India

Purifiers manufacturer

I will recommend anyone looking for Business loan to Le_Meridian they helped me with Four Million USD loan to startup my Quilting business and it's was fast When obtaining a loan from them it was surprising at how easy they were to work with. They can finance up to the amount of $500,000.000.00 (Five Hundred Million Dollars) in any region of the world as long as there 1.9% ROI can be guaranteed on the projects.The process was fast and secure. It was definitely a positive experience.Avoid scammers on here and contact Le_Meridian Funding Service On. lfdsloans@lemeridianfds.com / lfdsloans@outlook.com. WhatsApp...+ 19893943740. if you looking for business loan.

ReplyDeleteMr Lee recently helped us with a loan which we used to expand our business. The process was amazing! He was in touch with us frequently to check in and to update us on what was happening throughout our loan repayment. He was friendly and approachable and always able to clear up questions that we had. We had such a great experience working with Ben!!

ReplyDeleteContact A Loan Officer Ben Lee Email: 247officedept@gmail.com Whats-App: +1-989-394-3740